Harold H Harvey

age ~75

from Benton, LA

- Also known as:

-

- Harold Harry Harvey

- Harry H Harvey

- Harold Harvey Harold

Harold Harvey Phones & Addresses

- Benton, LA

- 401 Elmwood St, Bossier City, LA 71111

- Shreveport, LA

- 1117 12Th St, Cape Coral, FL 33909

- Burlington, NC

- Bougere, LA

License Records

Harold E Harvey Md

License #:

8774 - Expired

Category:

Medicine

Issued Date:

May 1, 1947

Effective Date:

Aug 10, 2000

Type:

Physician

Resumes

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey

view sourceMedicine Doctors

Harold A. Harvey

view sourceSpecialties:

Hematology/Oncology

Work:

Penn State Hematology Oncology

500 University Dr, Hershey, PA 17033

7175318401 (phone), 7175310647 (fax)

500 University Dr, Hershey, PA 17033

7175318401 (phone), 7175310647 (fax)

Education:

Medical School

Univ of West Indies, Fac Med Sci, Kingston, Jamaica (566 01 Eff 1/71)

Graduated: 1970

Univ of West Indies, Fac Med Sci, Kingston, Jamaica (566 01 Eff 1/71)

Graduated: 1970

Procedures:

Chemotherapy

Conditions:

Malignant Neoplasm of Female Breast

Anemia

Bladder Cancer

Hodgkin's Lymphoma

Kidney Cancer

Anemia

Bladder Cancer

Hodgkin's Lymphoma

Kidney Cancer

Languages:

Chinese

English

Spanish

English

Spanish

Description:

Dr. Harvey graduated from the Univ of West Indies, Fac Med Sci, Kingston, Jamaica (566 01 Eff 1/71) in 1970. He works in Hershey, PA and specializes in Hematology/Oncology. Dr. Harvey is affiliated with Penn State Milton S Hershey Medical Center.

Harold E. Harvey Ii

view sourceSpecialties:

Internal Medicine, Allergy & Immunology

Work:

Harold E Harvey II MD PLLC

214 Professional Park, Beckley, WV 25801

3042525343 (phone), 3042526542 (fax)

214 Professional Park, Beckley, WV 25801

3042525343 (phone), 3042526542 (fax)

Education:

Medical School

St. George's University School of Medicine, St. George's, Greneda

Graduated: 1988

St. George's University School of Medicine, St. George's, Greneda

Graduated: 1988

Procedures:

Allergen Immunotherapy

Allergy Testing

Electrocardiogram (EKG or ECG)

Pulmonary Function Tests

Skin Tags Removal

Vaccine Administration

Allergy Testing

Electrocardiogram (EKG or ECG)

Pulmonary Function Tests

Skin Tags Removal

Vaccine Administration

Conditions:

Abdominal Hernia

Acne

Acute Conjunctivitis

Acute Sinusitis

Acute Upper Respiratory Tract Infections

Acne

Acute Conjunctivitis

Acute Sinusitis

Acute Upper Respiratory Tract Infections

Languages:

English

Description:

Dr. Harvey II graduated from the St. George's University School of Medicine, St. George's, Greneda in 1988. He works in Beckley, WV and specializes in Internal Medicine and Allergy & Immunology. Dr. Harvey II is affiliated with Beckley ARH Hospital and Raleigh General Hospital.

Harold B. Harvey

view sourceSpecialties:

Family Medicine

Work:

Harrison Peeples Health CareBeaufort Memorial Harrison Peeples Health Care Center

1000 Pne St W, Varnville, SC 29944

8039435228 (phone), 8039434591 (fax)

1000 Pne St W, Varnville, SC 29944

8039435228 (phone), 8039434591 (fax)

Languages:

English

Spanish

Spanish

Description:

Mr. Harvey works in Varnville, SC and specializes in Family Medicine. Mr. Harvey is affiliated with Beaufort Memorial Hospital and Hampton Regional Medical Center.

Isbn (Books And Publications)

-

Aquatic Environmental Quality: Problems And Proposals

view source -

Author:Harold H. Harvey

-

ISBN #:0660008785

Us Patents

-

Cutting Tool For Removing Man-Made Members From Well Bore

view source -

US Patent:50388592, Aug 13, 1991

-

Filed:Dec 27, 1988

-

Appl. No.:7/290575

-

Inventors:Gerald D. Lynde - Bossier City LA

Harold H. Harvey - Bossier City LA -

Assignee:Tri-State Oil Tools, Inc.

-

International Classification:E21B 2900

-

US Classification:166 556

-

Abstract:A cutting tool (10) for removing metal tubular members held in stationary position downhole from a well bore and adapted to be inserted within a well. The cutting tool (10) includes a plurality of elongate blades (32,34) on the cylindrical body (22) of the cutting tool (10) which extend below the bottom of the tool body (22). Cutting elements (42) of a predetermined size and shape are arranged in a symmetrical predetermined pattern on the lower portion of each blade (32,34) in a plurality of predetermined transversely extending rows below the tool body (22). The cutting elements (42) in adjacent transverse rows for each blade (32) are staggered horizontally and have different concentric cutting paths. Preferably, the cutting elements (42) in corresponding transverse rows on adjacent blades (32,34) are staggered and have different concentric cutting paths. Each cutting element (42) has a groove (42F) for receiving and directing forwardly the extending end of a metal shaving (S) to facilitate breaking thereof from the upper end of the tubular member (14) being cut away.

-

Cutting Tool For Removing Materials From Well Bore

view source -

US Patent:50586661, Oct 22, 1991

-

Filed:Dec 3, 1990

-

Appl. No.:7/621063

-

Inventors:Gerald D. Lynde - Bossier City LA

Harold H. Harvey - Bossier City LA -

Assignee:Tri-State Oil Tools, Inc. - Bossier City LA

-

International Classification:E21B 1026

-

US Classification:166 556

-

Abstract:A cutting tool (10) for removing members downhole from a well bore and adapted to be inserted within a well from the upper end (12) of the casing (14). The cutting tool (10) includes a plurality of elongate blades (32) on the cylindrical body (18) of the cutting tool (10). Cutting elements (42) of a predetermined size and shape are arranged in a symmetrical predetermined pattern on each blade (32) in side-by-side relation in a plurality of predetermined transversely extending rows and a plurality of predetermined generally vertically extending columns. The cutting elements (42) in adjacent transverse rows for each blade (32) are staggered and have different concentric cutting paths. The cutting elements (42E) in corresponding transverse rows on adjacent blades (32A, 32B) are staggered and have different concentric cutting paths. The blades (32A, 32B) of the embodiment of FIGS.

-

Milling Tool For Cutting Well Casing

view source -

US Patent:47967099, Jan 10, 1989

-

Filed:Jan 6, 1986

-

Appl. No.:6/816287

-

Inventors:Gerald D. Lynde - Bossier City LA

Kenneth W. Winterrowd - Shreveport LA

Harold H. Harvey - Bossier City LA -

Assignee:Tri-State Oil Tool Industries, Inc. - Bossier City LA

-

International Classification:E21B 2900

-

US Classification:166 556

-

Abstract:A milling tool (10) for processively cutting away a section of casing (14) installed within a well from the upper annular end (12) of the casing (14). The milling tool (10) includes a plurality of elongate blades (32) equally spaced from each other at intervals between one and three inches about the periphery of the cylindrical body (18) of the milling tool (10). The blades (32) are inclined with respect to the axis of rotation and hard carbide cutting discs (34) arranged in horizontal rows on the blades (32) form the inclined leading planar face of the blades (32), and the lowermost row of discs (34) forms a cutting edge with a negative rake engaging the upper end (12) of the casing (14) in a cutting operation.

-

Downhole Milling Tool

view source -

US Patent:58100792, Sep 22, 1998

-

Filed:Oct 10, 1995

-

Appl. No.:8/541551

-

Inventors:Gerald D. Lynde - Houston TX

Harold H. Harvey - Bossier City LA -

Assignee:Baker Hughes Incorporated - Houston TX

-

International Classification:E21B 1026

-

US Classification:166 556

-

Abstract:A tool for cutting or milling casing in a well is disclosed. It includes a plurality of blades extending outwardly to a substantially radial position for cutting the walls of casing strings and removing a predetermined length of the casing strings in a cutting action. The blades have cutting elements positioned on leading faces of the blades to engage the casing strings in a cutting action without tripping or removal from the bore hole. The cutting elements can be arranged in rows and columns. The cutting elements can be shaped to continually present a sharp cutting edge to the object being milled. The cutting elements can be inclined at a negative axial rake angle to cause the metal chips cut from the object being milled to break off at short lengths. The cutting element can also have surface irregularities to cause the metal chips cut from the casings to break off at short lengths. The cutting element can also have stress relieving grooves to prevent the propagation of a crack across the face of the element.

-

Downhole Milling Tool

view source -

US Patent:58992685, May 4, 1999

-

Filed:Oct 28, 1997

-

Appl. No.:8/958829

-

Inventors:Gerald D. Lynde - Houston TX

Harold H. Harvey - Bossier City LA -

Assignee:Baker Hughes Incorporated - Houston TX

-

International Classification:E21B 1026

-

US Classification:166 556

-

Abstract:A tool for cutting or milling casing in a well is disclosed. It includes a plurality of blades extending outwardly to a substantially radial position for cutting the walls of casing strings and removing a predetermined length of the casing strings in a cutting action. The blades have cutting elements positioned on leading faces of the blades to engage the casing strings in a cutting action without tripping or removal from the bore hole. The cutting elements can be arranged in rows and columns. The cutting elements can be shaped to continually present a sharp cutting edge to the object being milled. The cutting elements can be inclined at a negative axial rake angle to cause the metal chips cut from the object being milled to break off at short lengths. The cutting element can also have surface irregularities to cause the metal chips cut from the casings to break off at short lengths. The cutting element can also have stress relieving grooves to prevent the propagation of a crack across the face of the element.

-

Downhole Milling Tool

view source -

US Patent:53739000, Dec 20, 1994

-

Filed:Jul 22, 1993

-

Appl. No.:8/096010

-

Inventors:Gerald D. Lynde - Houston TX

Harold H. Harvey - Bossier City LA -

Assignee:Baker Hughes Incorporated - Houston TX

-

International Classification:E21B 1026

-

US Classification:166297

-

Abstract:A tool for cutting or milling casing in a well is disclosed. It includes a plurality of blades extending outwardly to a substantially radial position for cutting the walls of casing strings and removing a predetermined length of the casing strings in a cutting action. The blades have cutting elements positioned on leading faces of the blades to engage the casing strings in a cutting action without tripping or removal from the bore hole. The cutting element has surface irregularities to cause the metal chips cut from the casings to break off at short lengths. The cutting element can also have stress relieving grooves to prevent the propagation of a crack across the face of the element.

-

Milling Tool For Cutting Well Casing

view source -

US Patent:50147781, May 14, 1991

-

Filed:Mar 18, 1988

-

Appl. No.:7/169836

-

Inventors:Gerald D. Lynde - Bossier City LA

Kenneth W. Winterrowd - Shreveport LA

Harold H. Harvey - Bossier City LA -

Assignee:Tri-State Oil TOols, Inc. - Bossier City LA

-

International Classification:E21B 2900

-

US Classification:166 556

-

Abstract:An oil field cutting tool (10) for progressively cutting away a tubular member (14) installed within a well from the upper annular end (12) of the tubular member (14). The cutting tool (10) includes a plurality of elongate blades (32) spaced about the periphery of the cylindrical body (18) of the cutting tool (10). A plurality of cutting elements (42) of a predetermined size and shape are secured in a predetermined pattern on the leading surface of the blades (32) in a plurality of closely spaced parallel rows extending transversely between the sides of the blades (32) and in a plurality of closely spaced parallel columns extending generally longitudinally between the ends of the blades (32).

-

Downhole Milling Tool

view source -

US Patent:54563127, Oct 10, 1995

-

Filed:Oct 17, 1994

-

Appl. No.:8/323815

-

Inventors:Gerald D. Lynde - Houston TX

Harold H. Harvey - Bossier City LA -

Assignee:Baker Hughes Incorporated - Houston TX

-

International Classification:E21B 1026

-

US Classification:166 556

-

Abstract:A tool for cutting or milling casing in a well is disclosed. It includes a plurality of blades extending outwardly to a substantially radial position for cutting the walls of casing strings and removing a predetermined length of the casing strings in a cutting action. The blades have cutting elements positioned on leading faces of the blades to engage the casing strings in a cutting action without tripping or removal from the bore hole. The cutting element has surface irregularities to cause the metal chips cut from the casings to break off at short lengths. The cutting element can also have stress relieving grooves to prevent the propagation of a crack across the face of the element.

Name / Title

Company / Classification

Phones & Addresses

Principal

Triple H Transport LLC

Transportation Services

Transportation Services

202 Doyal Rd, Benton, LA 71006

ALL Officers

FRONTIER DRILLING, INC

Incorporator

ELM STREET SEWER COMPANY, INCORPORATED

Director

H & R Enterprises of Lee County, Inc

2275 Cleveland Ave, Fort Myers, FL 33901

Flickr

Classmates

Harold Harvey

view sourceSchools:

Richmond High School Richmond VT 1955-1959

Community:

Nancy Lapan, Bill Goodrich, Glen Lyon, Elizabeth Martin, Betty Whiting

Harold Harvey

view sourceSchools:

Central High School Salt Lake City UT 1987-1991

Community:

Toni Steele, Cindie Taylor, Mark Heck, Lisa Metcalf

Harold Harvey

view sourceSchools:

Central High School Salt Lake City UT 1988-1992

Community:

Toni Steele, Cindie Taylor, Mark Heck, Lisa Metcalf

Harold Harvey

view sourceSchools:

Rindge Technical High School Cambridge MA 1953-1956

Community:

Brian Buckley, Carol Judkins

Harold Harvey

view sourceSchools:

Wilson High School Portsmouth VA 1941-1945

Community:

Janet Summerlyn, Frankie Biggs

Harold Harvey

view sourceSchools:

Rowan High School Hattiesburg MS 1960-1962

Community:

Dinah Hill, Ed Farmer, Albert Boles, John Duncan, Cleveland Hale

Harold Harvey

view sourceSchools:

Johnston Junior High School Houston TX 1943-1947

Community:

Roy Brewer, Julie Kirk, Anna King, Kathy Bernhardt, Richard Gaddis, Jeffrey Williams

Harold Harvey Tan

view source

Harold Harvey

view source

Harold L. Harvey

view source

Harold Harvey

view source

Harold Harvey

view source

Harold Harvey Pedralvez

view source

Harold Harvey

view source

Harold Harvey

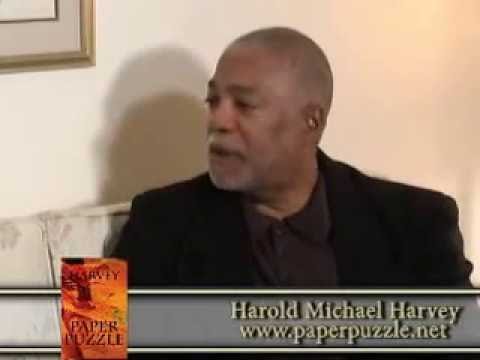

view sourceYoutube

Plaxo

Harold Harvey and Joan H...

view source2564 Honeysuckle Dr Richardson Texas 75082

Googleplus

Harold Harvey

Harold Harvey

Harold Harvey

Get Report for Harold H Harvey from Benton, LA, age ~75